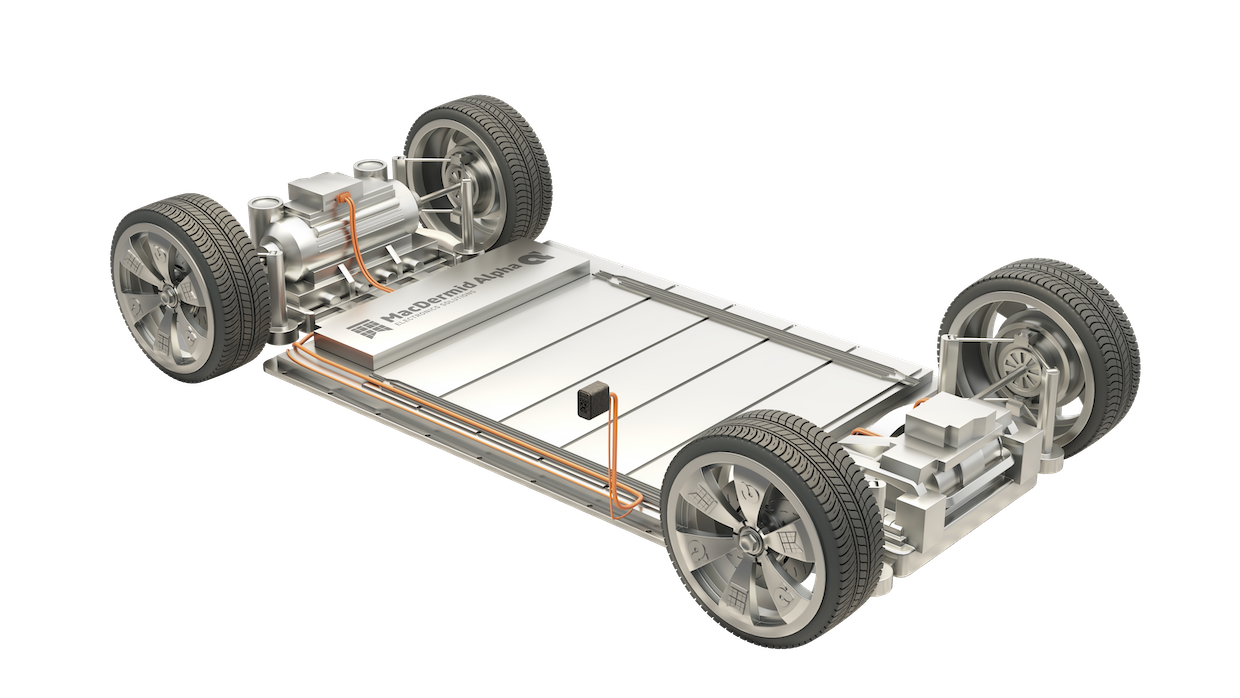

Improving electric vehicle power electronics

With the EV market growing at a rapid pace, manufacturing challenges also arise. As a result, it has become crucial that OEMs and Tier 1s develop the right technologies designed to enhance the performance of electric vehicles that also meet the needs of ever-connected consumers.

We offer a range of products and solutions suited to the electric vehicle industry.

- Our electronics division provides solutions for assembly and circuitry.

- Our industrial solutions provides processes for working with lightweight materials such as aluminum and magnesium.

Our expertise across the automotive supply chain enhances system-level solutions to the automotive industry.

Discover MacDermid Alpha Electronics Solutions’s global brands.

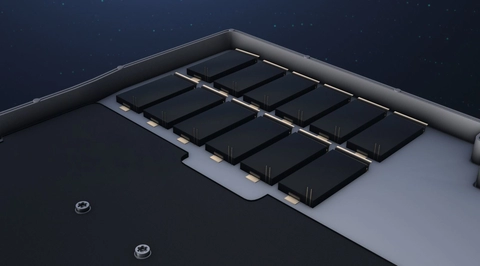

With vehicle electronics, everything is connected – through both circuitry and assembly. Our video below demonstrates how MacDermid Alpha Electronics Solutions aids electronic hardware reliability.