Sintered silver technology

contact us

Argomax® can improve efficiency by 40%, achieve a 75% reduction in die count and a 34% reduction in inverter weight, deliver double the power density, increase peak power through the inverter by a factor of six and deliver reliable performance through 2 million power cycles.

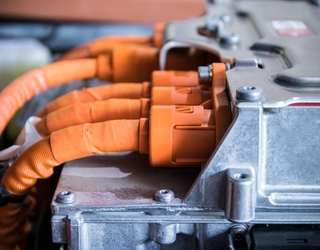

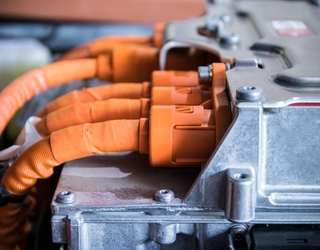

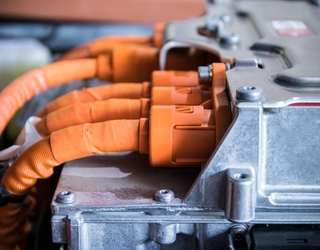

ALPHA® Argomax® sintered silver technology for die-attach, package attach and substrate-heat spreader attach significantly improves the efficiency and reliability of power electronics, such as traction inverters and other high voltage conversion applications, including onboard chargers and DC/DC converters.

Argomax® sintered silver has been successfully deployed in large volume electric vehicle (EV) automotive inverter applications, implemented with both discrete mini module silicon carbide MOSFETS as well bare die silicon IGBT - Diodes mounted on a ceramic substrate with a film laminated copper clip for topside die attach. Wirebonds and solder are eliminated to achieve high endurance power cycling capability, improved electrical characteristics, improved power density, and superior thermal performance.

By moving to sintered silver, and adopting the changes needed in the manufacturing process, the opportunity exists to realize significant performance and reliability gains today with current silicon die technology and establish a production platform for optimizing silicon carbide in the very near future.