Electroless nickel

contact us

Engineers tasked with designing modern electronics face a number of challenges. Expectations are for more functionality, more power, and more components in ever-smaller and lightweight packages.

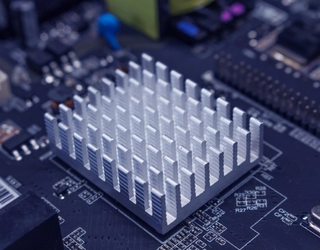

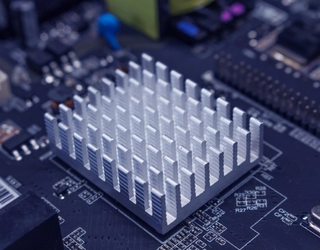

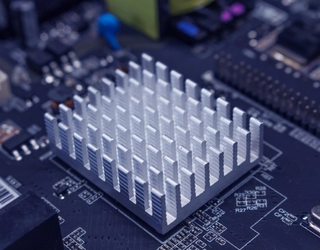

Thermal management is a key critical aspect of the design process. Aluminum heat sinks (Pin Fin) are designed to meet the requirements of modern electronics cooling.

As a consequence of lightweighting and miniaturization, automotive OEMs are challenging the aluminum industry and Tier 1’s to provide innovative new heat sink designs. A primary requirements is to facilitate the increasing cooling requirements for today's and future electrical vehicles.

Electroless nickel is the coating of choice for these heats sinks as it provides increased corrosion resistance. A major benefit of electroless nickel is that the deposit is completely uniform, even when applied to intricate shapes and designs.

Electroless nickel offers a wide range of deposit characteristics such as; wear protection, chemical resistance, corrosion protection and can be used for soldering and bonding purposes. Even complicated part geometries can be plated with high accuracy and layer thickness, exactly according to predefined specification drawings.

Find out more about electroless nickel coatings.