Automotive requirements are changing with demands for higher power, increasing reliability whilst miniaturizing and reducing components weight.

Compared to conventional soldered and wired power modules, the use of sintered silver technology enables a 34% weight reduction. Silver has many desirable properties, including extremely high thermal conductivity, and very low electrical resistivity. We partner with you to understand the specific requirements of each project to deliver the industry’s most lightweight and functional power invertors.

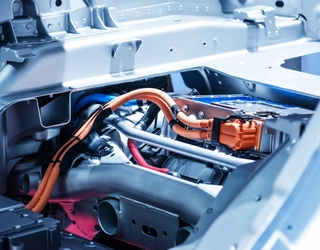

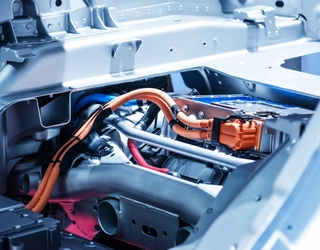

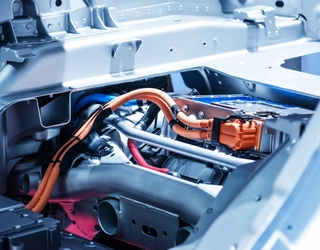

The automotive industry moves to introduce increasing numbers of electric vehicles. The reliability of the new powertrain components, including electric motors, battery, and power electronic components such as inverter and on-board charging circuitry plays an important role to determine market share growth for both start-ups and already established manufacturers.

- For EV technology lightweighting plays an important role. Although direct emissions are prevented due to the elimination of the combustion process, the emissions related to energy production still apply. The battery is about 25 % of the total weight of the vehicle. Depending on the vehicle type the battery could weight up to 800 kg. For this reason, lightweighting is extremely relevant with the objective to increase the range per charge for electric-powered vehicles. Conventional invertor power electronic modules are heavy large complicated components. Sintered silver technology ensures using full efficiency of power modules, by significantly reducing complexity, size, and weight off invertors.

- Silicon carbide is being looked at for next-generation semiconductor material. Compared to silicon, silicon carbide exhibits many attractive features where it is even more efficient, requiring significantly fewer devices for given power output. All these features result in additional lightweighting opportunities. Silicon Carbide however does not flex like silicon and is likely to fail much sooner during power cycling. We partner with you to establish a production platform for unlocking the true value of new silicon carbide semiconductor materials.