Carmakers urged to consider hardware reliability to avoid ADAS-related recalls

contact us

[Waterbury, CT, USA, January 20, 2022]

Automotive OEMs are being urged to take a systems-level approach to vehicle safety and confirm the reliability and inter-compatibility of hardware materials, as US regulators continue to shine a spotlight on Advanced Driver Assistance Systems (ADAS).

The message comes at a time when the National Highway Traffic Safety Administration (NHTSA) is continuing an investigation into ADAS systems following an alleged autopilot failure affecting certain vehicles.

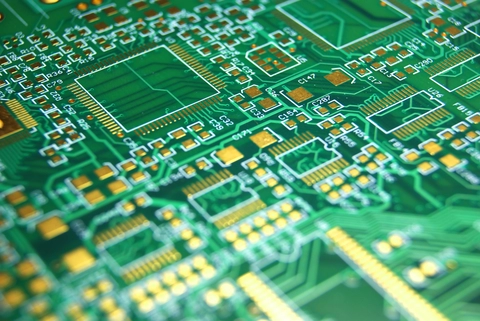

While the investigation is primarily focusing on ADAS software, MacDermid Alpha Electronics Solutions stresses the importance of hardware reliability in enabling the overall systems function. Something as small as a solder fracture in the PCB assembly materials can carry the risk of vehicle recalls and potential reputational damage for OEM brands. Carmakers must therefore pay as much attention to ADAS hardware as they do to software if they are to deliver continued reliable and trusted safety in future systems.

Lenora Clark, Director of Autonomous Driving and Safety Technology at MacDermid Alpha Electronics Solutions, explained: “ADAS systems are not only critical in today’s vehicles, but will grow in importance as carmakers move towards level three autonomy. For this to be achieved, the supply chain must work together to create systems that work both individually and together to create a safer, more efficient driving experience.

“To ensure required function and reliability of these systems, optimized material choices need to be made. This can only be done by specifying materials at a systems-level, understanding how different materials interact with each other and perform in challenging environments. As ADAS systems become more crucial to vehicles, their safety is already being tested rigorously and major industry bodies are involved in material assessments. OEMs must be confident that their materials pass the most stringent reliability tests – every single time.”

MacDermid Alpha Electronics Solutions claims that carmakers can achieve their design goals of integrating high levels of electronics systems for ADAS, by innovating for miniaturization and using unique substrates whilst still continuing to deliver the highest level of hardware reliability. It points towards other industries where electronic materials are constantly being pushed to increase function and maintain high reliability, such as consumer electronics and aerospace, as examples where lessons can be learned by automotive OEMs.

Clark continued: “At MacDermid Alpha Electronics Solutions, we take a holistic view of hardware. This perspective provides solutions that give carmakers greater design freedom through enhanced reliability and increased performance. As OEMs continue to work with the supply chain to innovate ADAS on the road to full vehicle autonomy, it is critical that hardware materials can cope with high operational cycles and challenging environments.”

For more information about ESI’s materials for ADAS hardware, click here