Who is really responsible for vehicle warranty issues?

contact us

Being an automotive OEM is full of challenges. Not only have major carmakers spent the past 12 months navigating production issues caused by covid-enforced plant closures, suffering raw material shortages, and attempting to transition towards mass EV production, it seems they are never far away from a potential production set-back.

Yet, few predicaments can cause quite the damage as a warranty-related recall. According to Warranty Week, in round numbers, the world's automakers spent roughly 2.5% of their product revenue, equivalent to slightly more than $49 billion, on warranty expenses during 2019. By the end of that fiscal year, they had just under $113 billion in their warranty reserves, and were setting aside an average of $539 in warranty accruals per car sold.

With these financial implications, it’s no surprise that carmakers are constantly preoccupied with improving their approach to warranty management. The benefits of warranty management go way beyond cost savings. Incremental quality improvements within the design of critical vehicle applications not only reduce the likelihood of warranty issues but can also have a directly positive effect on a carmaker’s brand.

Take ADAS (Advanced Driver Assistance Systems) as an example. A recent report by the National Law review concluded that ‘“there are 9.1 self-driving car accidents per million miles driven, while the same rate is 4.1 per million miles for regular vehicles.” Several OEMs have been involved in high-profile warranty recalls during the past few years as a consequence of ADAS failures.

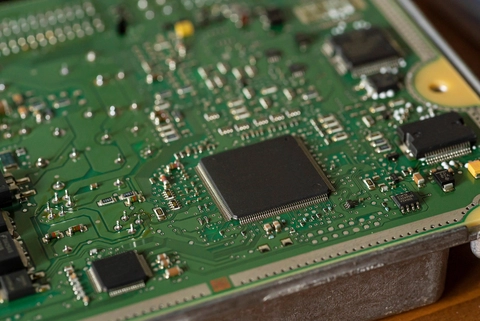

Where do the potential problems lie? Recent AAA research found that in 4,000 miles of real-world driving, ADAS suffered problems an average of every 8 miles. Today, software issues account for 60% of electronic failure (in vehicles). However, according to Ward’s auto “In the world of automotive recalls, software defects are declining, and attention is turning to the IECs (Integrated Electrical Components)”. In the USA for example, there is evidence of an increase in vehicles affected by IEC defects. Of these, some 600,000 vehicles required repair or replacement of equipment. Data suggests this increase is due to the ageing of electronic components.

Issues with ADAS are perhaps more concerning than any other vehicle component, when you consider that these systems grow in importance as automakers progress their vehicle designs to level three autonomy and beyond. As vehicles become more autonomous, they inevitably become more similar, particularly from a design perspective.

While consumers were once seeking high horsepower, these vehicles no longer have engines. Whereas cost of ownership was important, this will potentially be no more, since few people will own a vehicle outright in the age of true autonomy. Instead, one of the only ways in which an OEM will differentiate its vehicles is through its brand.

In the age of autonomy, a vehicle brand synonymous with reliability and safety is arguably more valuable than one with the latest gadgets, infotainment system, or even battery range. A reputation for safety can promote a positive company image, improve customer satisfaction and loyalty.

Ultimately, it is the carmaker who suffers in the event of a component failure. People rarely remember the name of a Tier 1 or 2 supplier – they always remember the name of the OEM.

As vehicle designs continue to become more sophisticated and autonomous, automakers are increasingly looking to play more of a role in componentry design.

One area where MacDermid Alpha Electronics Solutions is working across the supply chain with both Tier 1 Tier 2 and OEM businesses, is in ADAS design. Specifying the the optimum materials for ADAS hardwareoptimum materials for ADAS hardware can support the function and reliability of these systems, thereby reducing the risk of carmakers suffering an ADAS hardware-related recall.

MacDermid Alpha Electronics Solutions is working with the supply chain to view ADAS design at a systems-level, with a focus on the following three areas:

By working in partnership with the entire ADAS supply chain and collaborating with automakers, MacDermid Alpha Electronics Solutions is helping to take some of the risk out of ADAS design by working with materials that are formulated to improve reliability.

Find out how MacDermid Alpha Electronics Solutions can help with your ADAS project.