Can autonomous vehicle designs stand the heat?

contact us

Temperatures soared across much of Europe and the rest of the world this summer and keeping cool quickly became an essential staple of everyone’s routine. The human body is amazing in this respect; before you become too hot, the brain instinctively employs thermoregulation.

This delicate process maintains the body’s core internal temperature to ensure organs remain in a state of homeostasis, a self-regulating process in which biological systems maintain stability while adjusting to changing external conditions. A healthy body temperature regulates between 98°F (37°C) and 100°F (37.8°C) but can fluctuate depending on activity and external environments.

The hypothalamus is the part of the brain which serves as the command center for this process, intricately balancing heat production and loss, making necessary adjustments to keep the overall temperature within one or two degrees of 98.6°F to ensure optimal functionality. It works in partnership with other parts of the body’s temperature-regulating systems to balance fluids, maintain salt concentrations and release chemicals.

This awe-inspiring brain function draws a lot of parallels with ADAS – the ‘brain’ of a vehicle which just like the human body, needs all components to work in harmony to produce the desired result. This is particularly true with regards to thermal management.

Keeping organs at optimal capacity

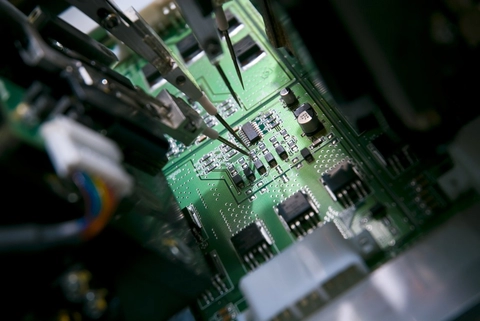

The heightened dependency on ADAS systems in vehicle designs that go beyond Level 2 autonomy, adds further pressure on electronic components – increased processing power produces excess heat which needs to be dissipated away from electronics to sustain performance and minimize the risk of component failure.

ADAS acts as the vehicle’s brain and therefore must be kept at the right temperature to maximize operational efficiency. Materials must withstand up to 3,000 thermal cycles, as a minimum. In addition, effective thermal management is critical to ensuring that advanced safety systems operate reliably within a broad range of environmental conditions.

One material that is particularly important when considering thermal reliability is die attach. This can be a point of weakness when exposed to thermal cycling in electronic packages. Traditionally, leaded solder was the go-to material for semiconductors, however due to legislation changes, lead containing alloys are now banned in most industries, with the EU automotive sector expected to follow suit by 2024.

As a result, the industry must seek out advanced materials, which share the same high temperature and thermal resistance as leaded solder, but while complying to REACH regulations.

Smaller and more efficient applications

An additional challenge in ADAS thermal management is miniaturization.

This burgeoning trend shows no signs of slowing down, with pressure on engineers to design electronics which are smaller, lighter, and faster. Yet as materials become more compact, their tolerances become more critical with limited design space and higher degrees of pressure.

Traditionally, 100+ packages are located in a vehicle for various in-car application; to facilitate rapid processing, manufacturers have introduced integration of multiple features into four to six high-processing powered electronic control units (ECUs). In a bid to further simplify the complex network and cabling requirements, Domain Control Units (DCU) were developed; a single centralized device which rapidly synthesizes data from multiple advanced driver safety systems including cameras, radar, and LiDAR, to help vehicles take immediate action.

Yet although DCUs dramatically improve efficiency, they too can buckle under the strain of exposure to elevated temperatures, a constant challenge for hardware which works faster and smarter. One successful alternative is Atrox, a lead-free alternative which utilizes a pressure-less system and extends the package’s life. I am increasingly working with OEMs and Tier 1s with this technology, which can be tailored to the precise demands of the application, whether for standard IC substrates, power packages or high-end applications.

OEMs and Tier 1s must withstand the heat

The human body must always withstand heat. Whilst the body moves and maintains basic functions, it generates energy and warmth and so the brain has the constant responsibility to manage the core temperature. Add to that, external forces including climate, exertion, clothing and stress and you begin to appreciate the tremendous effort it requires for the body to maintain equilibrium.

Vehicles are no different. Every time a car powers up, ADAS (the brain) treads a fine tightrope, balancing critical system functions and external aggressors to ensure a harmonious and efficient operating system, which keeps occupants safe. The component architecture needs to not only perform but do so constantly on a consistent basis to avoid hardware failures which could jeopardize performance, not to mention the financial and reputational implications for manufacturers.

Ultimately OEMs and Tier 1 suppliers must educate themselves on the intricacies of ADAS hardware; the journey has already begun towards autonomous vehicles; can your designs stand the heat?