How to achieve a giant leap in vehicle reliability

contact us

Lenora Clark, Director of Autonomous Driving and Safety Technology at MacDermid Alpha Electronics Solutions

On July 20, 1969, something as small and irrelevant as a pen saved the Apollo 11 mission.

Neil Armstrong and Buzz Aldrin had spent almost three hours on the moon’s surface collecting rock and dust samples. As they climbed back into the Lunar Module to return home, they discovered that a one-inch engine arm circuit breaker switch had broken off the instrument panel. This was the one vital breaker needed to send electrical power to the ascent engine that would lift them off the moon and take them back to earth. One of them had unwittingly knocked the switch off with their backpack.

They notified Mission Control by radio and began to think of a way to push something into the electrical circuit to help it hold - but they had already disposed of most of their tools aboard to make the module lighter. All they had left was a pen. Scrambling for an idea that would get the two astronauts safely back to earth, Aldrin used the pen to activate the inside switch, engaging the circuit breaker and triggering the engine. This created a complete circuit and started the engine, saving the mission – all thanks to a pen!

What does a pen have to do with vehicle reliability? Because it’s often the smallest things that trigger the biggest impact. Take ADAS hardware as an example. As we move towards level 3 vehicle autonomy, ADAS will be integral to ensuring vehicle reliability and occupant safety. However, something as small as a solder crack within the PCB assembly can cause hardware to fail, with potentially catastrophic consequences for carmakers.

There are solutions. For example, many OEMs are now adding conformal coatings and flooding circuit boards in attempt to give them additional protection. This can be expensive and is not always an effective long-term solution.

The reality is that traditional solder can no longer withstand the thermal cycles associated with modern vehicle systems. Today, ADAS hardware materials must withstand up to 3,000 thermal cycles to ensure long-term reliability. Not only do these systems undergo a high volume of processing which generates additional heat, but they also must withstand a constant cycle of aggressive heating and cooling, which can quickly lead to fractures and system failure.

What’s the solution? Something that can appear as small and irrelevant as that pen on the Apollo space mission!

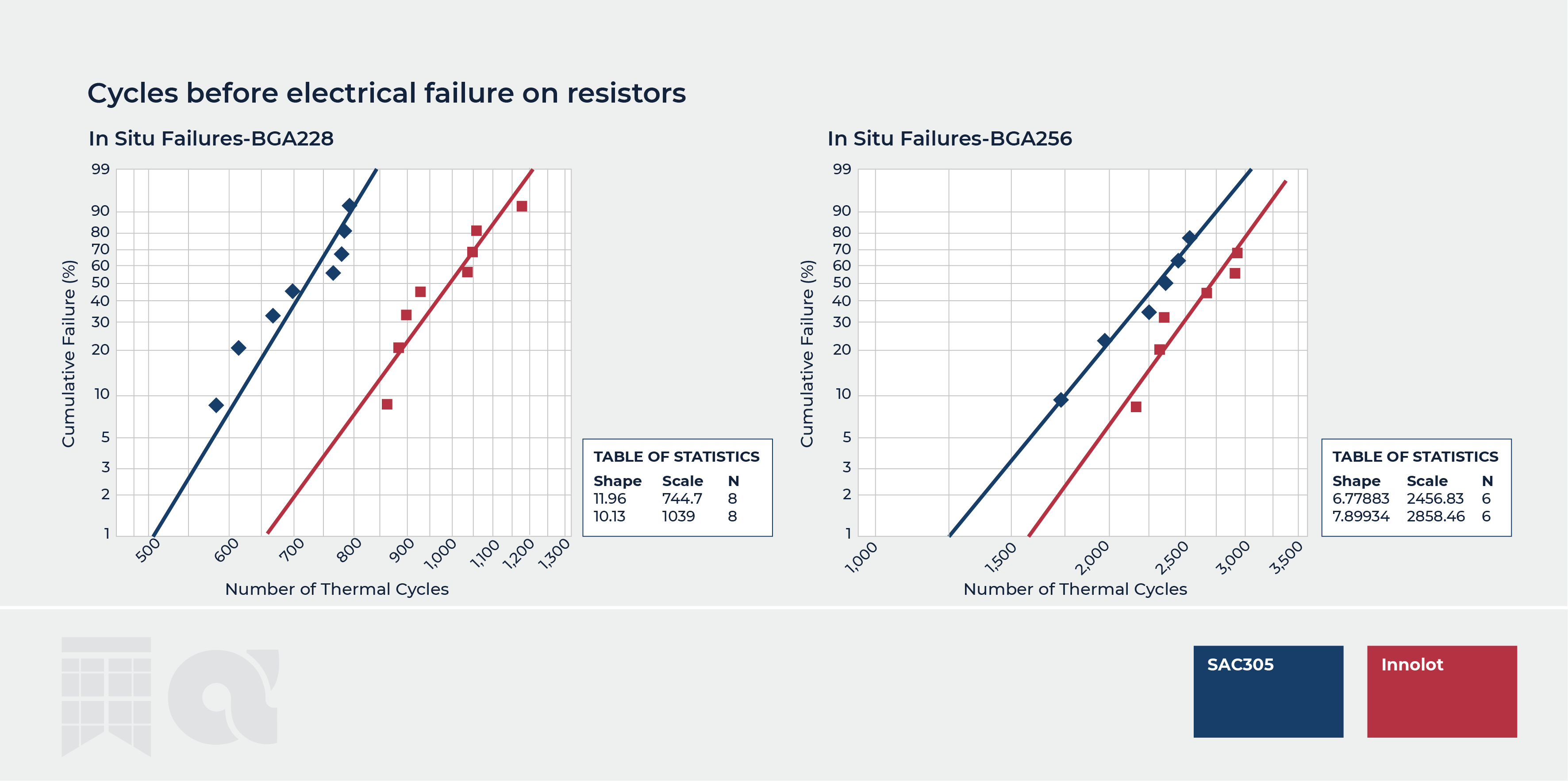

By replacing traditional solder for a high reliability alloy such as Innolot, it is possible to design an ADAS system that has more durable materials, potentially aiding overall vehicle reliability. MacDermid Alpha Electronics Solutions recently put the capabilities of Innolot to the test, comparing it to a traditional tin/silver/copper (SAC) alloy in a thermal cycle test. Our results indicate that the size of the package, pitch and the overall input and output do influence the characteristic life of the solder joint, as observed by the characteristic life of the package. In both cases, the alloy increased solder joint reliability by a defined percentage when compared to the traditional SAC alloy. In the case of a BGA228 package, the increase is 39.5%. For a BGA256 package, the increase is 16.3%.

The graphs above demonstrate the efficiency benefits of a high reliability Innolot alloy, when compared with a traditional SAC alloy

As OEMs continue to create reliable and connected vehicles, it is important to consider all elements of the design, since efficiency gains can be made in some of the unlikeliest areas with some of the smallest changes. Just as a pen saved the Apollo 11 mission, a small change in materials could result in a giant leap for vehicle reliability.