Introducing new electric vehicles

contact us

Chris Klok, Director, Vehicle electrification technology, MacDermid Alpha Electronics Solutions

As we’re entering a new decade, the EV market is growing at a rapid, yet anticipated pace. A huge area for investment, recent figures have suggested that almost a quarter of the vehicles being manufactured on the global market are expected to be non-ICE (internal combustion engine) by 2024. However, as the market continues to gain momentum, manufacturing challenges also arise. As a result, it has become crucial that OEMs and Tier 1s develop the right technologies designed to enhance the performance of electric vehicles, that also meet the needs of ever-connected consumers.

Regulations and future-proofing technologies: driving the EV market

The growth of the EV market is due to several factors. Environmental initiatives are key drivers in this, with legislation aimed at achieving carbon dioxide reduction targets across the world. Other regulations are also establishing fuel consumption and CO2 emissions of new cars, such as the Worldwide Harmonised Light Vehicle Test Procedure (WLTP) approvals implemented in 2017. Added to this, as the price inflection point of batteries gets lower, the cost-effectiveness of EVs becomes higher.

This combination of legislation and battery advancements continues to drive growth in the EV market. For example, in Europe, a possible move from the Euro 6 to Euro 7 emissions standard in the future will make it almost impossible to use the traditional internal combustion engine model. Innovation in EV power train components also have a big influence on the market, as companies look for an improved or an effective alternative, while still maintaining the same – or improved - power.

Supporting OEMs and Tier 1s throughout the value chain

With a rapidly evolving market, power efficiency and reliability in the electronics area are a prime concern for OEMs and Tier 1s. Providing these stakeholders with relevant knowledge on which technologies to use is therefore crucial to drive innovation. For MacDermid Alpha Electronics Solutions, as a provider of integrated solutions, sharing this information and our extensive industry knowledge enables our customers – from OEMs to Tier 1s to applicators - to have confidence in our products and services across the full value chain.

Our newly launched MacDermid Alpha Electronics Solutions strategic initiative allows us to work with all the interested organizations from the very start of the process and throughout the value chain. That means being in contact with engineers at the design level to meet their growing needs for next-generation vehicles – from both the substrate technology and assembly point of view. All these elements are crucial to the development of EVs and having expert knowledge throughout the supply chain allows us to offer this complete package.

Sustainability is also derivative of new product development, as we aim to create more reliable and efficient solutions for circuitry and assembly. We are already working to make EVs more efficient, more reliable and provide more power and reach, and we’re continuing these efforts with reliability and efficiency in mind.

Finding the right materials for new product development

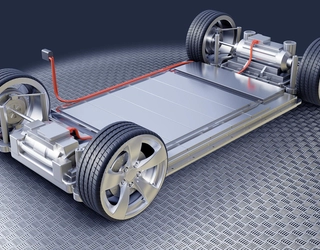

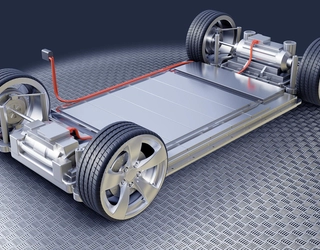

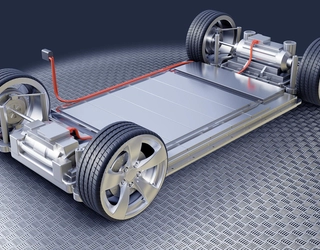

EVs require materials that aid in increasing the range, power efficiency and reliability - mainly in the electronics area. With electronics products, everything is connected – through both circuitry and assembly. More specifically, they are solutions that use Printed Circuit Board (PCB) and other substrates for semi-conductors and connectors. In the long run, for EVs, this could result in the use of fewer batteries, or those that extend range, which is an industry-wide challenge and ultimately can reduce vehicle manufacturing costs. If this happens, we could reach a point where EVs become cheaper to run than a vehicle with an internal combustion engine.

Our knowledge of the automotive sector means that we can stay up to date with the latest trends in the industry, including materials, and help provide solutions for associated challenges. For example, currently, the industry is looking towards silicon carbide to replace silicon on EVs, which allows for increased energy efficiency. However, this needs alternative assembly materials and that is where providers such as MacDermid Alpha Electronics Solutions can offer unique solutions for every step of the production process. This allows supply chain partners to have a single information point in the automotive market – whether they are an OEM, a Tier 1 supplier or a direct applicator of circuitry, joining or surface finishing technology.