How does MacDermid Alpha Electronics Solutions enable the trend of in-vehicle apps?

contact us

Look at images of concept cars interiors, and one aspect is almost universal; The size and reach of the display screens are increasing. Along with this trend is their increased functionality.

No longer is the screen just visual (see) or even just a data entry point (touch, like a smartphone) but a fully functional component with haptic feedback areas to guide the users’ fingers (touch and see).

All this is designed to continually improve the vehicle owners’ experience. Examples of these include connectivity and capacitive touch switches.

Connectivity offers multiple major advantages including in-car-services, advanced navigation, enhanced safety and lower fuel consumption .

In fact, connectivity is so important, that automotive manufacturers now exhibit concept and production vehicles at the Consumer Electronics Show (CES).

A sign that the line between consumer electronics and motor vehicles in become blurred .

According to a 2020 report by immersion.com 'users want the same multimodal, dynamic, responsive interfaces in their vehicles as they do on their mobile devices'. Capacitive switching allows the designer the ability to offer smartphone like responsive displays. Additionally the surface can be contoured. This gives the driver to 'sense' the switch by touch alone, crucial when driving.

Advanced circuitry + assembly technology + hardcoated films = In-mold electronics

Advanced circuitry + assembly technology + hardcoated films = In-mold electronics

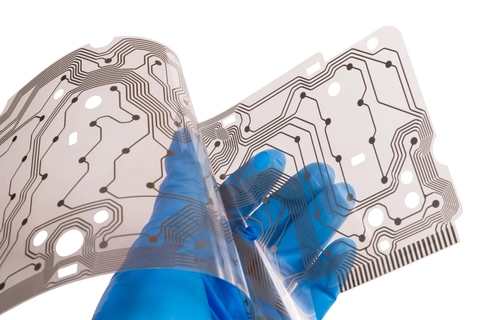

In-mold electronics are created by integrating advanced circuity and conductive inks on hardcoated displays. Having all these 3 technologies in our portfolio, MacDermid Alpha Electronics Solutions is in a unique position to achieve this.

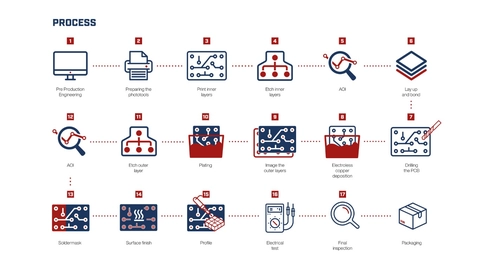

MacDermid Alpha Electronic Solutions chemical processes are found in all the PCB manufacturing stages. Additionally, our technology is used in electronic components such as connectors, substrate packages and molded plastic parts. We apply the lessons learned from the high technology aerospace and handheld industries to the revolutionary innovation of connected automobiles.

Our assembly division, Alpha, provides high performing materials for surface mount technology, including conductive inks. Powered by experience with all types of electronics, the portfolio ranges from low temperature joining technology through high reliability applications. This knowledge forms a critical understanding of joining circuitry to plastic hardcoated films.

The final piece in creating in-mold electronics is the user interface, or display. The current trend to deliver increasing numbers of displays, seamlessly into automotive cockpits presents significant challenges for designers. These challenges can be overcome using high-performance, hardcoated films to address the 5 decision making criteria of weight, materials, optics, sparkle and clarity.

How does MacDermid Alpha Electronics Solutions enable the trend of in-vehicle apps? We believe we are the only company which supplies all the products for advanced circuitry, assembly technology and hardcoated films.

In-mold electronics expertise? MacDermid Alpha Electronics Solutions are already on it.