Improving range by optimizing power electronics

contact us

Extending the driving range of electric vehicles (EVs) is one of the key challenges in the automotive industry. Silver sintering is an effective alternative to conventional solder that increases the efficiency of EV traction inverters.

The global EV market looks set to grow in the coming years: the result of new emissions regulations in Europe and China in 2020/21 and the subsequent penalties if manufacturers fail to meet fleet emissions targets. Global sales of non-fossil fuel vehicles reached 7.8 million in 2021, almost 11% of all passenger cars. LMC predicts that non-fossil fuel-driven cars will grow by a CAGR of 15% over the next with 7 years, over 30% of total volume. In the same period, full battery electric vehicles will grow to 10%, from 3% today.

The EV market varies significantly from region to region, depending on local regulations and government subsidies. With the International Energy Agency (IEA) setting an ambitious global target of getting 250m EVs on the road by 2030 as part of the Sustainable Development Scenario (SDS), significant steps need to be taken in the coming years to unlock the full potential of these vehicles.

Increasing range continues to be a key challenge in the more widespread adoption of EVs, as it requires greater battery capacity, which

not only raises the cost of the vehicle but also adds weight. There is a delicate balance between improving the energy density of a battery and limiting vehicle performance – causing many OEMs to look at other options to help boost vehicle range.

Power electronics are emerging as an area that could help extend driving range. For instance, efficient power conversion in the traction inverters is key to improving range, through lower electrical resistance and higher reliability of the die bond to the lead frame and heat sink. Such advances in EV technologies that increase driving range and reduce costs will likely expand uptake even more.

For EVs with a certain battery size, driving range is directly related to the efficiency of the power train"

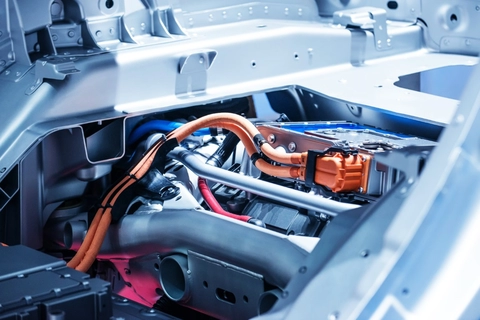

For EVs with a certain battery size, driving range is directly related to the efficiency of the power train. As such, inverters are a growing area of focus for automotive OEMs and Tier 1s. There are critical power conversion electronics that sit between the DC battery source and the AC motor. By improving the efficiency of the power conversion, either the vehicle range can be extended, or the battery size can be reduced to achieve the same range using current inverter technology.

Current designs use silicon-based power modules with soldered and wire bonded interconnects. Compared to bulk silver, solder alloys have much lower thermal and electrical conductivity. They also have lower melting points, limiting the temperature at which the devices can be operated. If higher operating temperatures can be achieved, OEMs can significantly improve efficiency by using silicon carbide semiconductors.

Silver sintering can help overcoming the thermal dissipation and high-temperature stability challenges associated with traditional power module interconnects. The technology works by sintering the silver particles to form bulk silver bonds through atomic diffusion. This provides a bond with higher stability and lower thermal resistance than solder and allows much higher operating temperatures.

Stringent testing shows that silver sintering technology helps to create more efficient inverters. For example, the technology reduced the cumulative thermal resistance of the stack (from die to the pin-fin heat sink) by approximately 10%. These figures improve over time with power cycling. Studies show that a typical sintered silver interconnection has a bulk density of approximately 85%. After an additional 350,000 power cycles, the density increases to more than 94%, further reducing the thermal resistance of the interconnections. The same test found that all the solder-wirebond parts had failed by the time 12,000 cycles were completed. This indicates that a fully sintered device can switch more current at the same temperature, helping to make significant performance and reliability improvements.

There is an opportunity to significantly increase the range of an electric vehicle by using silver sintering technology to optimize the bonds of the power semiconductor package. The use of advanced materials enables more efficient connections, which improve the power conversion of the traction inverter.

Experienced manufacturers can help advise OEMs and Tier 1s on the right material and technology to optimize power electronics and extend range. MacDermid Alpha Electronics Solutions is a leading provider of advanced circuitry, joining materials, and surface finishing technology, with an in-depth understanding of the full value chain. Our specialist knowledge across the global automotive supply chain enhances system-level solutions to industry challenges of performance, as well as reliability and form factor.