Reliability and efficiency: what's the most important EV investment for automotive OEMs?

contact us

When it comes to electric vehicle (EV) design, the need to create more fuel-efficient vehicles is often stressed largely due to the sustainability benefits. However, an equally as important topic on the minds of OEMs surrounds reliability. Reliability is not just important in terms of warranty and minimizing the risk of product recalls, but also from a go-to-market perspective since standards exist all around the world for electric vehicles. Several of today’s carmakers in Europe offer manufacturer warranties of five years or more, with unlimited miles for their vehicles with internal combustion engines. Will manufacturers still believe in the robustness of their EVs by offering today’s lengthier warranties on cars that do not have a traditional engine?

Defining reliability

Before answering this question, it is worth considering the true industry definition of reliability. For consumers, reliability often relates back to the product as a whole. For vehicle design teams, the term connotates safety and quality. As an example: It is essential that the materials used for joining and plating components are highly reliable; that they perform well under extreme operating conditions, and ensure high performance at all times, particularly within the vehicle powertrain.

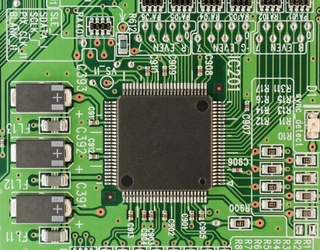

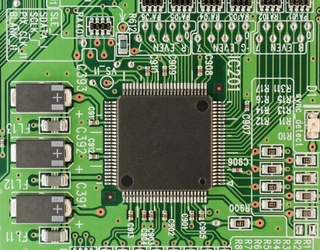

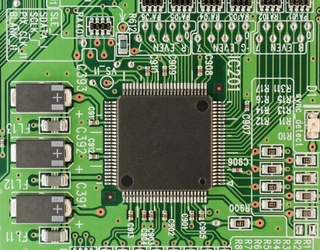

Reliability is essential within the power electronics system of an electric vehicle, where overall performance and differentiation are defined. These power electronics are the most activated part of electric cars, required to simulate power cycles at high operating temperatures. Essential to this is the inverter. However, stringent testing indicates that traditional solder alloys used in inverter design may not be able to withstand thermal and mechanical pressure on solder joints, increasing the risk of product failures. What could be achieved with a different approach?

What’s the solution to greater EV reliability?

One solution to improving the EV reliability score is through silver sintering, which enables the design of much smaller, lighter and more reliable systems. Sintered silver, as a method of component attach, can increase the power and reliability of the traction inverter, the critical power conversion electronics that sit between the DC battery source and the AC motor. In some applications, replacing traditional solder and wire bonds with a fully sintered top and die attach, can increase the power density capability of the joint by more than 80%. Furthermore, silver sintering technology can streamline circuitry in inverters to reduce heat loss and improve power output, for additional range reliability.

Through effective material selection, it is also possible to improve reliability for soldered joints on critical control PCBA’s in the vehicle powertrain system. This is particularly beneficial for components within the power electronics, which experience a lot of heat and vibration. When using Innolot solder alloy as a replacement for conventional soldered interconnections, electric car designers can more than double the service life of in-vehicle powertrain components.

In every car today many electronic control units (ECU) are used, and there are tens of thousands of conventionally soldered surface mount joints in the power electronics. Depending upon design constraints, using Innolot solder alloy can improve the fatigue life of those interconnections. Not only are Innolot solders more reliable than tin-silver copper alloy counterparts, but in harsher environments, the automotive electronics assemblies are also able to withstand higher operating temperatures and vibration stress,

As the only automotive supplier for both plating and joining materials, MacDermid Alpha Electronics Solutions is able to provide a deep understanding of how different approaches to materials and engineering techniques can reap major gains in EV reliability. With unparalleled chemistry knowledge, we support automotive electronics manufacturers and OEMs to design higher-performing, more reliable and efficient electric vehicles – so there’s never a need to compromise between reliability and efficiency.