QPS

-

Meeting directives, such as ELV REACh and RoHS continues to be essential requirements. QPS delivers on all of these needs. QPS complies with the conditions set forth in the ISO 9001: 2015.

QPS helps automotive engineers to specify the right products in a sustainable world. The steady evolution of the program has enabled many global OEM’s to specify ever-higher performance standards and represents:

- Approved applicators: Applying these products to a common audited standard ensures the same coating performance throughout the applicator base.

- High performance: Exceeding the high demands for corrosion resistance and exceptionally consistent torque and tension characteristics.

- Global consistency: Wherever standards are applied, applicators know they are using the same high-performance products.

What do we do?

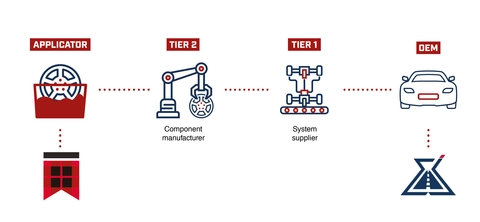

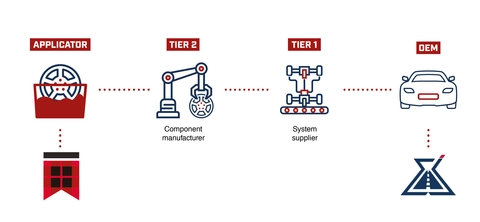

Image

We supply and develop QPS standards that meet and exceed OEM specifications. We validate applicators processes by conducting audits, carrying out inspections and testing the production output to make sure they meet pre-defined QPS standards and agreed technical requirements.

We monitor and report results on a global scale to be able to service and continuously improve performance.

Why do we do what we do?

We believe that we are able to assure a global consistent performance at a local level meeting the global OEM requirements with a select number of world class applicators.

How do we do what we do?

MacDermid Enthone Industrial Solutions has developed a unique Quality Performance System called QPS that tackles the challenges for high-performance automotive coatings. OEM’s can be confident that the same coatings and consistent performance are available worldwide.